R&D and Design

At VTM-UTAM, our penchant for innovation is reflected in the efforts we put in to constantly develop new products and also explore effective ways to meet customer demands in terms of product reliability, longevity, energy efficiency and Safety.

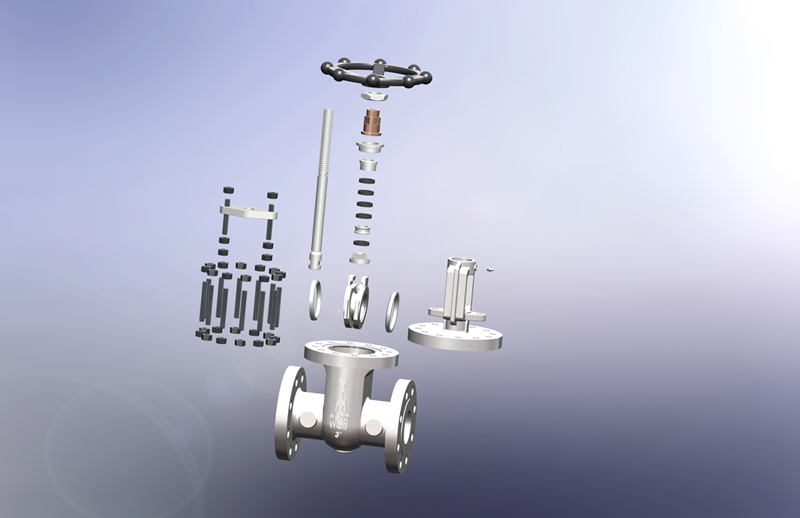

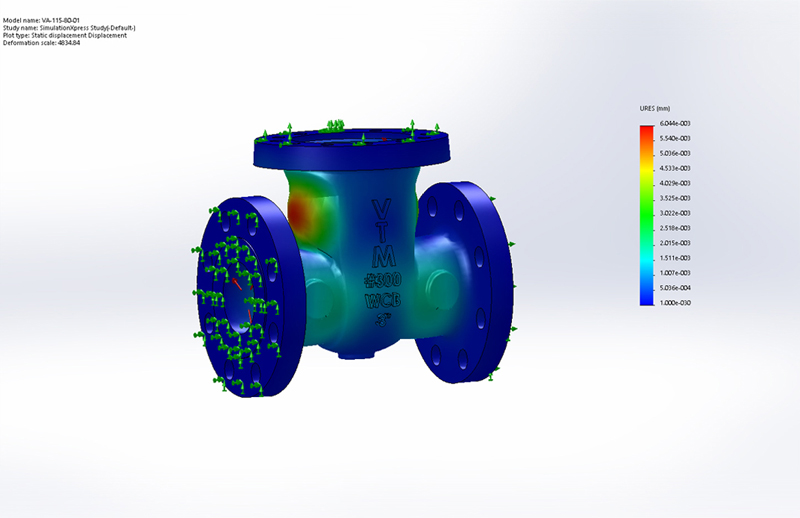

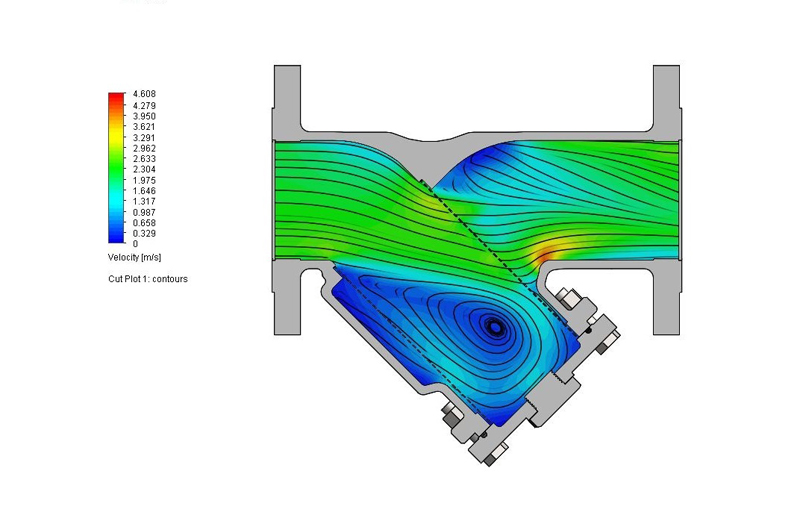

To help foster innovation across all levels, we have invested heavily in deploying state-of-the art design and simulation techniques such as specialized 3D modelling software along with FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) tools.

All VTM products are designed following internationally accepted stringent design procedures in compliance with various International standards. A typical product development life cycle at VTM includes:

Project Conception

Review of the respective design standards such as ISO, API, NACE, ASME, ASTM, MSS-SP, BS EN, PED, etc.

Review of engineering calculations

FEA & Simulation. All valve parts are simulated for integrity using Finite Element Analysis. The valve assembly is simulated using Computational Fluid Dynamics (CFD) for desired flow characteristics.

Detailed Drawings of all valve parts.

Our team of skilled Design Engineers consistently monitors any updates in the respective design standards and incorporates any applicable changes that affect the design / performance of our products.

3D MODELING

STRESS ANALYSIS

CFD SIMULATION